Certainly! click here for more details on the download manual…..

- IS THIS HOW OUR RV JOURNEY ENDS? | CRASH VIDEO! After two years of traveling full time in our RV, we crashed. This is part of the crash video. We want to document how we move past …

- dash ac overhaul class a 2003 coachmen f53

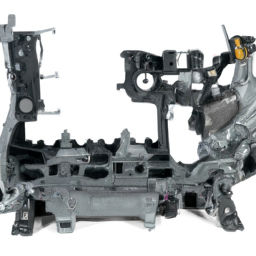

Repairing the suspension knuckle on a Ford F53 chassis might sound complicated, but I’ll break it down into simple steps. The suspension knuckle is an important part of the vehicle’s steering and suspension system. It connects various components, such as the wheel hub and control arms, and helps to support the vehicle’s weight and ensure a smooth ride.

### Tools and Materials Needed:

– Safety gear (gloves, goggles)

– Jack and jack stands

– Wheel chocks

– Socket set and ratchet

– Wrench set

– Hammer

– Torque wrench

– New suspension knuckle (if you’re replacing it)

– New bearings and seals (if needed)

– Grease

### Step-by-Step Guide:

#### 1. **Safety First**

– park your vehicle on a flat surface and turn off the engine.

– Engage the parking brake and use wheel chocks to prevent the vehicle from rolling.

#### 2. **Lift the Vehicle**

– Use a jack to lift the front of the vehicle. Make sure it’s high enough to work comfortably under it.

– Place jack stands under the vehicle for extra safety. Never work under a vehicle supported only by a jack.

#### 3. **Remove the Wheel**

– Use a socket and ratchet to loosen and remove the lug nuts on the wheel you’re working on.

– Take off the wheel and set it aside.

#### 4. **Remove the Brake Components**

– If your vehicle has disc brakes, you’ll need to remove the brake caliper. Use a wrench to unbolt it and hang it using a hook or bungee cord to avoid straining the brake line.

– Remove the brake rotor If necessary, which may involve removing additional bolts.

#### 5. **Disconnect the Tie Rod and Control Arm**

– Locate the tie rod (the part that connects the steering to the wheel). Use a wrench to unbolt it from the knuckle.

– If there are control arms connected to the knuckle, you’ll need to remove those bolts as well. This may require some effort.

#### 6. **Remove the Old Suspension Knuckle**

– Check for any additional components connected to the knuckle, like the wheel hub or bearings. You may need to remove these as well.

– Once everything is disconnected, you can unbolt the knuckle from its mount on the vehicle and carefully remove it.

and carefully remove it.

#### 7. **Inspect and Prepare the New Knuckle**

– Before installing the new knuckle, inspect it for any damage. Also, check the bearings and seals; replace them If they look worn out.

– Apply a bit of grease to the new bearings and seals for smoother operation.

#### 8. **Install the New Suspension Knuckle**

– position the new knuckle where the old one was and bolt it into place according to the manufacturer’s specifications.

– Reattach any components you previously removed (tie rod, control arms, wheel hub).

#### 9. **Reinstall the Brake Components**

– Put the brake rotor back on and then reattach the brake caliper. Make sure everything is tightened securely.

#### 10. **Reattach the Wheel**

– Put the wheel back on and hand-tighten the lug nuts.

– Lower the vehicle back to the ground and then use a torque wrench to tighten the lug nuts to the manufacturer’s specifications.

#### 11. **Final Checks**

– Before taking the vehicle for a test drive, double-check that all bolts are tightened and everything is reconnected properly.

– Take the vehicle for a short drive to ensure everything is functioning well.

### Conclusion

Repairing a suspension knuckle requires careful attention and some basic mechanical skills, but by following these steps methodically, you can successfully complete the job. If at any point you feel unsure, it’s always best to consult a professional mechanic.