Replacing suspension dampers on a DEUTZ engine involves several steps and requires specific tools and safety precautions. click here for more details on the download manual…..

- Deutz Ford Ranger Diesel Conversion – 1984 Ranger F3L912 Swap The process of swapping an air-cooled F3L 912 3 cylinder Duetz Diesel into my 1984 Ford Ranger pickup truck. No turbo.

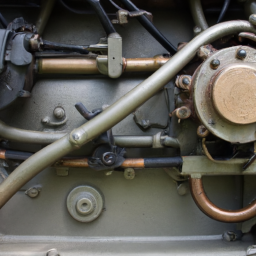

- Deutz engine 413 F8L v8 Restarting check the engine

Below, I’ll provide a detailed breakdown of the components involved, tools required, and the procedure for replacing the suspension dampers.

### Components Involved:

1. **Suspension Dampers (Shock Absorbers)**: These are the main components that absorb shock and vibrations from the engine and the vehicle’s suspension system.

2. **Mounting Brackets**: These brackets secure the dampers to the engine frame and the suspension components.

3. **Bushings**: Rubber or polyurethane components that provide cushioning and reduce vibration. These are typically located within the mounting brackets.

4. **Bolts/Nuts**: Fasteners that secure the dampers and mounting brackets to the frame. These may require specific torque specifications.

5. **Tools**:

– Socket set (including ratchet and extensions)

– Wrenches

– Torque wrench

– Screwdrivers

– Pliers

– Pry bar (if necessary)

– Jack and jack stands (if working on a vehicle)

– Safety glasses and gloves

### Safety Precautions:

– Ensure the engine is turned off and cool before starting.

– Disconnect the battery to avoid any electrical issues.

– Use jack stands to support the vehicle if it is elevated.

– Wear safety glasses and gloves to protect yourself from debris and sharp objects.

### Procedure for Replacing Suspension Dampers:

1. **Preparation**:

– Park the vehicle on a flat, stable surface. If necessary, elevate the vehicle using a jack and secure it with jack stands.

– Disconnect the battery to prevent any electrical hazards.

2. **Access the Dampers**:

– Depending on the layout of the DEUTZ engine and the vehicle, you may need to remove other components (like covers or panels) to access the dampers. Use a screwdriver or socket set to remove any panels.

3. **Remove the Old Dampers**:

– Locate the bolts that secure the dampers to the mounting brackets. Use the appropriate socket or wrench to remove these bolts. Keep track of any washers or spacers.

– If the damper is stuck, you may need to use a pry bar gently to loosen it.

– Carefully detach the damper from the brackets and remove it from the engine or suspension assembly.

4. **Inspect and Replace Bushings**:

– Check the condition of the bushings. If they are worn or damaged, replace them. Remove the old bushings from the mounting brackets and install new ones By pressing them into place or following manufacturer instructions.

5. **Install the New Dampers**:

– Position the new dampers in place. Ensure that they align correctly with the mounting brackets.

– Insert the bolts through the brackets and dampers, adding any washers or spacers as necessary.

– Tighten the bolts to the manufacturer’s specified torque using a torque wrench. This is critical to ensure proper function and safety.

6. **Reassemble**:

– If you removed any components to access the dampers, reinstall them in the reverse order of removal.

– Ensure all connections are secure and that nothing is left loose.

7. **Final Steps**:

– Reconnect the battery.

– Lower the vehicle (if it was elevated) and remove jack stands.

– Start the engine and check for any unusual noises or vibrations that may indicate an issue with the installation.

8. **Test Drive**:

– Take the vehicle for a short test drive to ensure that the new dampers are functioning correctly. Pay attention to how the vehicle  handles and listen for any abnormal sounds.

handles and listen for any abnormal sounds.

### Conclusion

Replacing suspension dampers on a DEUTZ engine requires careful attention to detail and adherence to safety procedures. By following these steps and ensuring that all components are correctly installed and secured, you can effectively replace your dampers and improve the overall performance of your vehicle’s suspension system. Always refer to the specific manual for your DEUTZ engine model for any unique instructions or torque specifications.

The exhaust manifold gasket is a critical component in an internal combustion engine, serving as a seal between the exhaust manifold and the cylinder head. This gasket plays a vital role in ensuring the proper functioning of the exhaust system By preventing exhaust gases from leaking out before they are directed through the exhaust system and ultimately out of the vehicle.

Typically made from materials like composite fibers, metal, or a combination of both, the exhaust manifold gasket is designed to withstand high temperatures and pressures generated during the combustion process. The gasket must maintain its integrity to avoid leaks, which can lead to a range of issues, including decreased engine performance, increased emissions, and potential damage to surrounding components.

Over time, factors such as heat cycling, vibration, and exposure to corrosive exhaust gases can cause the gasket to deteriorate, leading to potential failures. Symptoms of a failing exhaust manifold gasket may include a noticeable exhaust leak noise, reduced engine performance, increased fuel consumption, and the illumination of the check engine light.

Replacing a worn or damaged exhaust manifold gasket is essential for maintaining engine efficiency and ensuring that the vehicle complies with emissions regulations. The replacement process typically involves removing the exhaust manifold, cleaning the mating surfaces, and installing a new gasket to restore a proper seal. Regular maintenance checks can help identify issues with the exhaust manifold gasket before they lead to more severe engine problems.