Replacing the anti-roll bar on a Lombardini LDA 422 engine can sound complicated, but with a step-by-step approach, it can be made simpler. click here for more details on the download manual…..

- Como Sincronizar Motor Lombardini 15LD440/S Sincronización de motor lombardini 15LD440/S. Puesta a punto y funcionamiento de equipo.

An anti-roll bar (also known as a sway bar) helps reduce body roll in a vehicle during turns. Here’s a basic guide for someone with little mechanical experience:

### Tools and Materials Needed:

1. **Basic Tools**:

– Socket set

– Wrench set

– Screwdriver set

– Pliers

– Torque wrench

2. **Replacement Anti-Roll Bar**: Make sure you have the correct part for your Lombardini LDA 422 engine.

3. **Safety Gear**: Gloves and safety glasses.

4. **Jack and Jack Stands**: To securely lift the vehicle (if applicable).

5. **Workshop Manual**: For specific torque settings and diagrams.

### Steps to Replace the Anti-Roll Bar:

#### 1. Safety First

– **Park the Vehicle**: Make sure the vehicle is on a flat surface and turned off.

– **Set the Parking Brake**: This prevents the vehicle from rolling.

– **Wear Safety Gear**: Put on gloves and safety glasses.

#### 2. Lift the Vehicle (If Necessary)

– **Jack Up the Vehicle**: If the anti-roll bar is located under the vehicle, use the Jack to lift it. Place Jack stands securely under the vehicle to support it.

#### 3. Locate the Anti-Roll Bar

– **Find the Anti-Roll Bar**: It is usually a metal rod that connects the left and right sides of the suspension. It helps keep the vehicle stable during turns.

#### 4. Remove the Old Anti-Roll Bar

– **Inspect the Connections**: Look for bolts or brackets holding the anti-roll bar in place.

– **Loosen the Bolts**: Using the appropriate socket or wrench, carefully loosen and remove the bolts securing the anti-roll bar. Keep track of the bolts and any washers.

– **Detach the Bar**: Once all bolts are removed, gently pull the anti-roll bar out from its mounts.

#### 5. Install the New Anti-Roll Bar

– **Position the New Bar**: Take the new anti-roll bar and align it with the mounts where the old bar was attached.

– **Secure with Bolts**: Insert and hand-tighten the bolts to hold the bar in place. Do not fully tighten yet.

#### 6. Tighten the Bolts

– **Use a Torque Wrench**: Following the specifications in the workshop manual, use a torque wrench to tighten the bolts to the proper torque setting. This ensures that everything is secured correctly without damaging the parts.

#### 7. Check Everything

– **Inspect the Installation**: Make sure the anti-roll bar is secure and that all bolts are tightened. Look for any loose parts.

#### 8. Lower the Vehicle (If Applicable)

– **Remove Jack S tands**: If you lifted the vehicle, carefully lower it back to the ground.

tands**: If you lifted the vehicle, carefully lower it back to the ground.

#### 9. Test Drive

– **Take a Test Drive**: Once everything is back in place, take the vehicle for a short, cautious drive to ensure everything is functioning properly. Listen for any unusual noises.

### Final Tips:

– **Consult the Manual**: Always refer to the vehicle’s workshop manual for specific details about your model.

– **Take Your Time**: Don’t rush. It’s important to do each step carefully to avoid mistakes.

– **Ask for Help**: If you’re unsure at any point, don’t hesitate to ask someone with more mechanical knowledge for assistance.

By following these steps carefully, you should be able to replace the anti-roll bar on a Lombardini LDA 422 engine successfully.

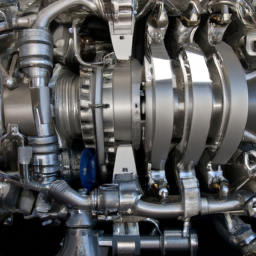

The timing chain is a crucial component in an internal combustion engine that plays a vital role in synchronizing the rotation of the engine’s crankshaft and camshaft. This synchronization is essential for ensuring that the engine’s valves open and close at the correct times during each cylinder’s intake and exhaust strokes. Unlike a timing belt, which is made of rubber, a timing chain is constructed from metal links, making it more durable and capable of lasting longer under extreme conditions.

The timing chain is typically located inside the engine and is driven by the crankshaft. It wraps around sprockets Attached to both the crankshaft and camshaft(s) and maintains precise timing as the engine operates. Over time, however, timing chains can stretch or wear, which may lead to a misalignment between the crankshaft and camshaft. This misalignment can cause severe engine performance issues, including reduced efficiency, increased emissions, or even catastrophic engine failure if the timing chain breaks.

Regular maintenance is essential to ensure the longevity of a timing chain. While they generally do not require replacement as frequently as timing belts, it’s important for vehicle owners to be aware of any unusual noises, such as rattling or clanking, which could indicate a failing timing chain. In summary, the timing chain is a critical component that ensures the smooth and efficient operation of an engine, making it a key element in automotive engineering.