Replacing a ball joint on a Case W11B loader can be a challenging task, especially if you have little mechanical experience. click here for more details on the download manual…..

- CASE W11B Financing available with rates starting at 5.25%. If you don’t see what you’re looking for visit dbequip. com and click on our ‘want …

- Case W20C review and walk around 951 Rick Sanchez www.tractortip.com.

However, with the right instructions and some patience, you can tackle it. Here’s a simplified step-by-step guide:

### Tools and Materials Needed:

1. **Tools:**

– Socket set (metric and standard)

– Wrenches (adjustable and regular)

– Hammer

– Ball joint separator tool (or a pickle fork)

– torque wrench

– pry bar

– Jack and jack stands

– Safety glasses and gloves

2. **Replacement Parts:**

– New ball joint

– Grease (if the joint is greasable)

– Any gaskets or seals if needed

### Safety Precautions:

– **Ensure safety:** Always wear safety glasses and gloves.

– **Work on a flat surface:** Make sure the loader is parked on a level surface.

– **Secure the vehicle:** Use jack stands when lifting the loader to prevent it from falling.

### Step-by-Step Instructions:

1. **Preparation:**

– **Disconnect the battery:** This is important to prevent any electrical issues while you work.

– **Locate the ball joint:** The ball joint is usually found at the end of the control arm connecting the wheel assembly.

2. **Lift the Loader:**

– Use a jack to lift the front of the loader and place jack stands underneath for safety. Ensure it’s stable before you start working.

3. **Remove the Wheel:**

– If necessary, remove the wheel to have better access to the ball joint. Use a socket wrench to take off the lug nuts and remove the wheel.

4. **Disconnect the Tie Rod (if applicable):**

– If the ball joint is connected to a tie rod, you may need to remove it. Use the ball joint separator tool to disconnect it gently.

5. **Remove the Old Ball Joint:**

– **Remove retaining bolts:** Locate the bolts that hold the ball joint in place and remove them using the appropriate socket or wrench.

– **Use a ball joint separator:** Insert the separator tool between the ball joint and the control arm and gently tap it with a hammer until the joint pops out. Be careful not to damage surrounding components.

6. **Install the New Ball Joint:**

– **Align the new joint:** Position the new ball joint into the control arm where the old one was located.

– **Secure it in place:** Insert and tighten the retaining bolts. Use a torque wrench to ensure they are tightened to the manufacturer’s specifications (check the service manual for the correct torque).

7. **Reconnect the Tie Rod:**

– If you removed the tie rod, reconnect it to the ball joint and secure it.

8. **Reattach the Wheel:**

– Place the wheel back on and hand-tighten the lug nuts. Once the wheel is on, lower the loader back to the ground and then use the torque wrench to tighten the lug nuts to the specified torque.

9. **Reconnect the Battery:**

– Once everything is back together, reconnect the battery.

10. **Test the Loader:**

– Before operating the loader, do a visual inspection to ensure everything is in place. If possible, take a short test drive to ensure everything functions properly.

### Final Notes:

– **Take your time:** Rushing can lead to mistakes or accidents.

– **Consult the manual:** If you have access to the loader’s service manual, refer to it for specific torque values and any unique steps related to your model.

and any unique steps related to your model.

– **Seek help if needed:** If at any point you feel uncertain, don’t hesitate to ask for assistance from someone with more mechanical experience.

By following these steps, you should be able to replace the ball joint on a Case W11B loader. good luck, and stay safe!

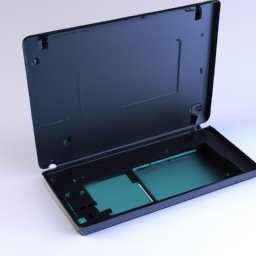

The hood of a car, often referred to as the engine cover, is a crucial component of a vehicle that serves both functional and aesthetic purposes. Typically made from materials such as steel, aluminum, or composite materials, the hood is designed to protect the engine and other vital components located in the front of the vehicle. It acts as a barrier against environmental elements, such as rain, dirt, and debris, thereby ensuring the longevity and performance of the engine.

In terms of functionality, the hood provides access to the engine compartment, allowing for maintenance tasks such as oil changes, coolant checks, and battery replacements. This ease of access is vital for vehicle maintenance and repair, making it an essential feature for mechanics and car owners alike. The design of the hood also plays a significant role in the vehicle’s aerodynamics, influencing airflow and contributing to the car’s overall performance and fuel efficiency.

From an aesthetic standpoint, the hood contributes to the vehicle’s exterior design and style. Manufacturers often incorporate various curves, lines, and finishes to enhance the car’s visual appeal, thereby making it more attractive to consumers. Additionally, some hoods are designed with vents or scoops that can improve engine cooling or performance, especially in high-performance or sports vehicles. Overall, the hood is not just a protective cover; it is a fundamental component that balances practicality, maintenance accessibility, and design aesthetics in modern automotive engineering.