24-valve gob of grease and smooth it into the hole. click here for more details on the download manual…..

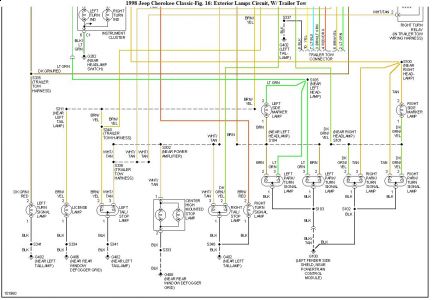

- Most common problems with 1997-2001 jeep Cherokee xj The most common problem I have found with the Cherokee Want some good tires check out treadwright http://www.treadwright.com/?afmc=f6.

- "Fixed" The Rust on my Jeep XJ for less than $100?!?! Getting closer and closer to my Jeep looking and feeling more “clean”

Be sure that the grease fills the races inside the hub where the bolt fills them. If your spare youll have to get your

Be sure that the grease fills the races inside the hub where the bolt fills them. If your spare youll have to get your

.

.

Disclosure of Material Connection: Some of the links in the post above are ‘affiliate links.’ This means if you click on the link and purchase the item, we will receive an affiliate commission. We are disclosing this in accordance with the Federal Trade Commissions 16 CFR, Part 255: ‘Guides Concerning the Use of Endorsements and Testimonials in Advertising.’